Some Ideas on Extrusion Of Plastics You Should Know

Wiki Article

Rumored Buzz on Plastic Extruded Profiles

Table of ContentsTop Guidelines Of Plastic Extrusion ProfilesCustom Plastic Extrusion Manufacturers Things To Know Before You Get ThisUnknown Facts About Plastic Extrusion CompaniesGet This Report about Custom Plastic ProfilesGetting My Custom Extrusion Manufacturer To Work

At Vip, we have years of experience manufacturing countless distinct custom-made plastic extrusions in virtually every shape, size, and also shade you can picture - https://www.directorystock.com/author/k3ll3rpl4st8/. Our specialty hinges on making plastic accounts especially for a specific application. You inform us what you need and also we will certainly produce it, satisfying the highest possible top quality standards.From pre-prototype to post-production, ACE has the capacity and innovation to do everything. We serve large and also little companies in industries varying from automobile to medical, with challenging product needs to tight resistances in America, Canada, Mexico, and Europe. Despite where you are or what industry you stand for, you can rely on ACE for customized solution and client satisfaction.

That indicates fast quotation service or product referral is just a phone call away - https://dev.azure.com/johnwynn03103/Keller%20Plastics/_wiki/wikis/Keller-Plastics.wiki/1/Not-known-Factual-Statements-About-Plastic-Extrusion-Manufacturers. Your concerns are constantly responded to without delay by our skilled solution team, and also you receive the assistance you require with no delays or confusion. Thanks for seeing our website, we are right here to assist you. Please contact your ACE sales representative at 414-332-8133 or email to review services and products.

The 45-Second Trick For Custom Plastic Profiles

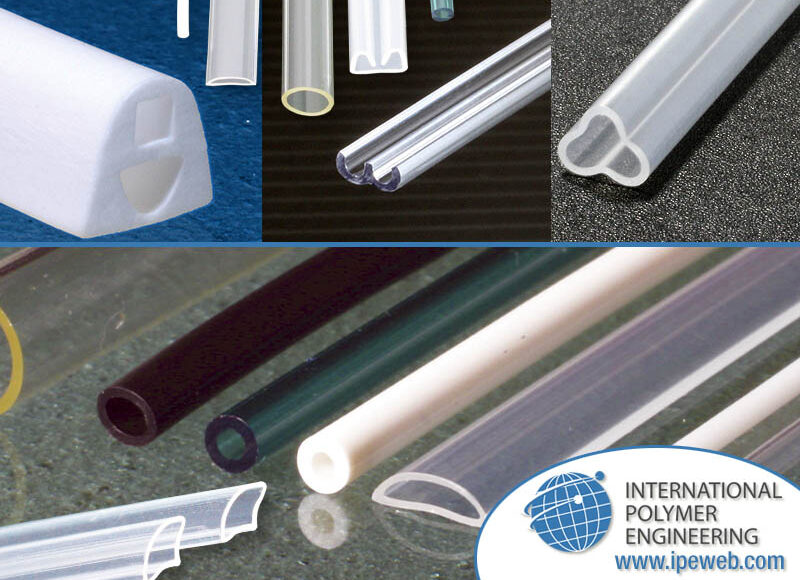

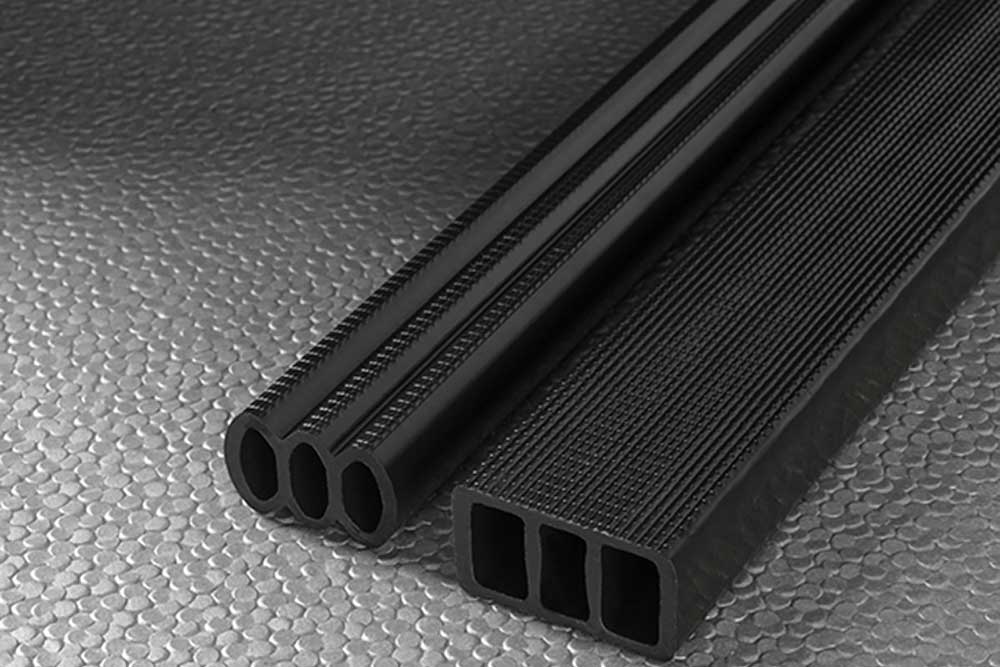

With over 100 combined years of experience in plastic extrusion, GSH Industries is a top B2B distributor of custom plastic extrusions, tubes, and plastic profiles in Northern Ohio. Our designers as well as engineers can aid you in selecting the very best products for your item line - https://www.producthunt.com/@k3ll3rpl4st8. We have a huge selection of plastic materials and can match any kind of customized colors to your consumer's specs - custom extrusion manufacturer.It is among one of the most prominent methods plastic parts are presently created because of its flexibility. Custom-made extrusions can be formed right into intricate forms of varying densities, staminas, dimensions, colors, and also structures, and also are relatively simple to function with. The extrusions can also be formulated with performance enhancing features such as fire resistance, improved resilience, improved strength, anti-friction or anti-static residential or commercial properties, and also a lot more.

It can likewise potentially result in longer cooling time with will certainly enhance your general production time and also expenses. Sharp corners as well as notches create weak factors in the account where cracking or failure can occur given that they minimize the impact resistance of the profile by producing a high anxiety focus. When possible, when designing your profile extrusion sharp corners ought to be prevented completely instead aim for rounded edges.

The Best Guide To Custom Extrusion Manufacturer

Preferably the distance should be equal to the wall thickness of the extrusion. This adds to smoother product circulation throughout extrusion and also much less stress on the profile's edges. They require additional adjustments to the die to ensure appropriate product circulation, can trigger irregular cooling, and also can trigger locations of weak point that can result in failing.If your component must have hollows, a hollow within one more hollow is never a great suggestion. It will certainly be displaced of form prior to the extrusion solidifies - https://k3ll3rpl4st8.edublogs.org/2022/11/04/get-this-report-about-custom-extrusion-manufacturer/. If your extrusion calls for attributes such as legs, grooves, snap-ins, or other items within the extrusion it is best to make an easily accessible opening right into the extrusion to make sure that you can better incorporate those features.

Some Known Factual Statements About Custom Plastic Extrusion Manufacturers

Knowing some clients might be unknown with our plastic account extrusion capabilities, we have actually compiled a checklist of questions we are often asked. Durometer is a dimension of the material's firmness as well as is determined with a tool which is pushed versus the account's surface area, causing a dial guage reading.

Common ranges are Coast A for flexible products and also Shore D for inflexible substances. Dual durometer, or co-extrusion, is the blend of two or more materials of differing physical residential or commercial properties right into a single extruded piece. An example would certainly be a rigid get rid of versatile fingers that plastic extruded profiles could be utilized as a gasket or pillow.

Depending on the part complexity as well as raw materials, one might approximate the prices starting at much less than $1,000. Due to varying set up prices and run performances, we try to limit the minimum manufacturing amount to 1,000 lineal feet.

Custom Plastic Extrusions Fundamentals Explained

First, what creates the line. If you take a close take a look at a drawing for a plastic account with an intersection leg, you will certainly see there is even more mass in the area of the crossway. Because thermoplastic materials diminish some during the cooling process, the crossway of two legs cools at a slower rate than the remainder of the profile, triggering it to reduce more because of the mass of the account.

A device designer would usually divide the circulation of both legs within the die, and also allow them to find back with each other as the extrudate is being compressed to the front of the extrusion die. This can sometimes create a weld line where both thaw streams are brought back with each other so mindful adjusting of the extrusion tooling is important to lessen this line.

Report this wiki page